About UPVC Profile

WinTech UPVC Profiles

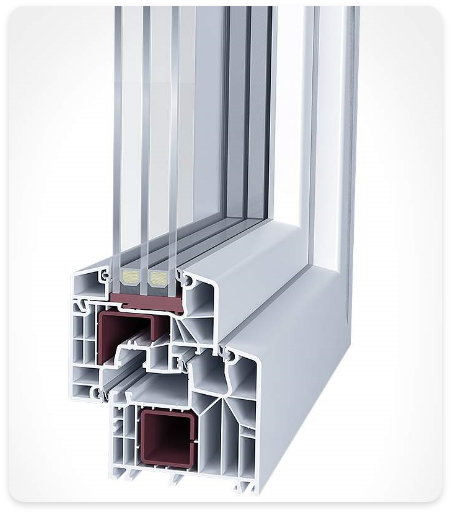

WinTech UPVC profiles are produced by specialized machines using the high quality PVC material reinforced with titanium dioxide TIO2 for the purpose of protection from the sun, as well as adding the needed stabilizers to protect the surfaces of the material from any scratches. In WinTech, the manufacturing processes are based on ensuring the dimensional accuracy of the final product to be in compliance with German quality standards RAL RG 716/1

About UPVC Profile

UPVC is an eco-friendly material, and stands for the chemical compound (Unplasticized Polyvinyl Chloride). It is mostly used as an alternative to Aluminum or painted wood to make window frames, glass facades, and sills, especially when using double glazing.UPVC has also replaced cast iron in the manufacture of drainpipes and gutters. What distinguishes UPVC from PVC is the letter U, which indicates that plasticizers are not added, so this material remains solid, able to face all climatic conditions, and has a long-lasting character

About UPVC Profile

WinTech UPVC profiles features

Sound Insulation

- u-pvc profile has the quality and thickness that give it the high insulation properties

- u-pvc profile has the quality and thickness that give it the high insulation properties

- Possibility of adding insulating glass (double glass)

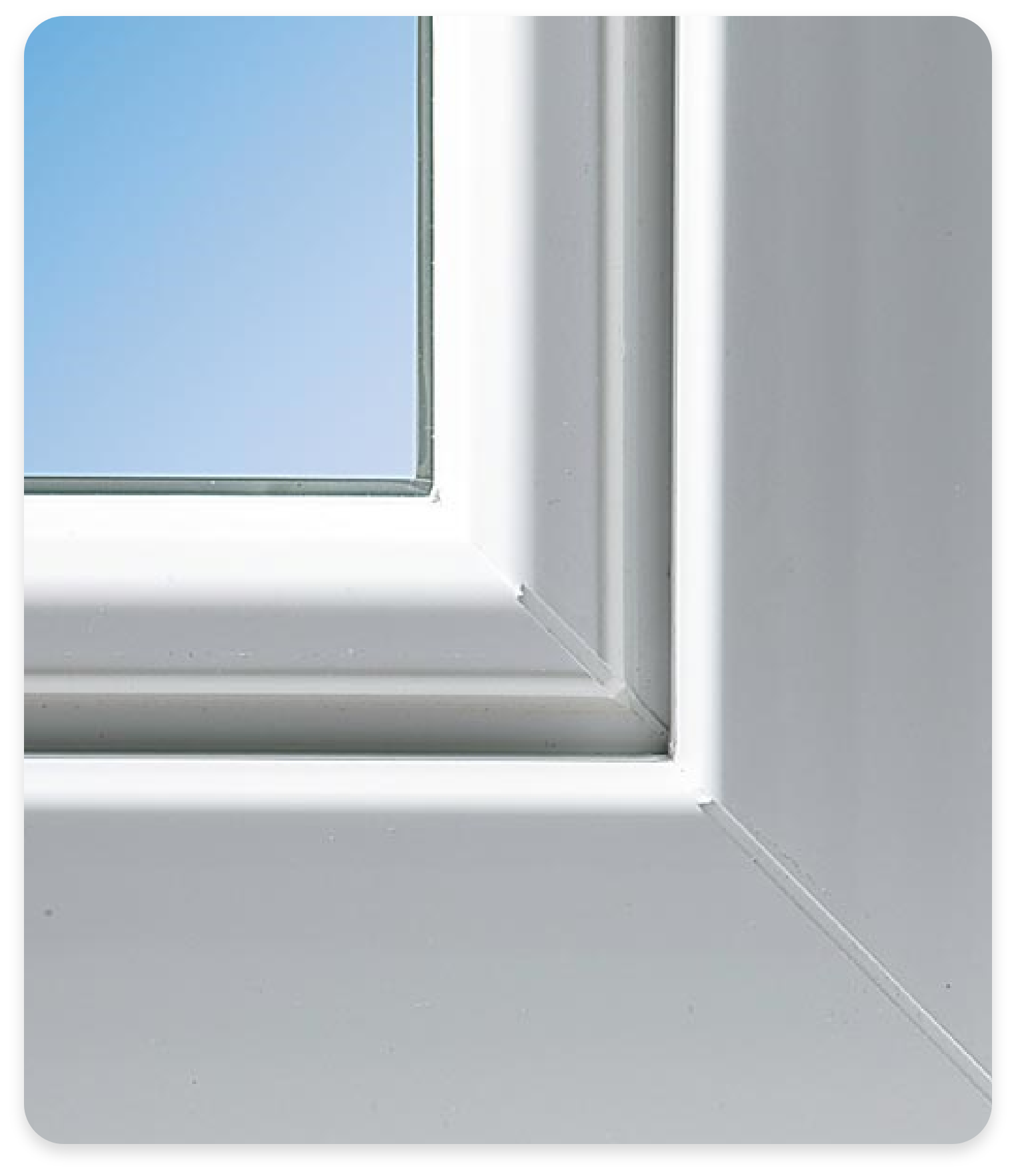

- Angles assembled by heat welding

Efficiency in power consumption

- The hollow spaces inside the sections help to increase the sound and heat insulation, thus saving the energy needed for air conditioning and heating, because most electrical appliances are programmed for automatic disconnection when the room temperature reaches a certain temperature.

- The tight closure of windows and doors resulting from the multiple points of overlap of the locks with each other also provides protection against theft because the locks are of multi-center, whether in the pull or open system

Weather Resistance

- Withstanding to the high and low temperature (40° – 85° C), bearing in mind that the melting phase of UPVC starts from -170° C

- Resistant to wind according to EN 12210 and rain water leakage according to EN 12208

- As for the zipper profile, they are characterized by the high density brushes on the shutter to prevent water, air and dust from entering

- The corners of the profiles are joined by heat welding to ensure optimal insulation of air currents

Technical Specifications

- Thermal expansion coefficient 0.8*10-4 k-1

- Thermal conductivity 0.16 W/MK

- Electrical resistivity 1016 Ω

- Heat transferring according to the used double glass (insulating glass) 1.4 – 2.6 W/M2 K

- The thickness of profiles is 2.5mm

- The black gaskets (TPV, TPV,EPDM,TPE)

Durability

- Matching global standard EN7748

- 46g/cm3 thickness that ensure the quality of profiles materials

- Air permeability is rated 4 according to EN 12207

Low Maintenance

- WinTech UPVC system also special due to its supposed long life comparing with the alternative systems because it has 9% of Tio2 which is resistant for sunlight and dust.

- WinTech UPVC systems are distinguished by the different kinds of profiles that are resistant for sunlight, so that it still has stable appearance and painting

Customizability

- Processing and machining techniques (drilling/sawing/chilling/smoothing/welding) can be applied

- Many ways to open windows and doors: zipper, horizontal or vertical opening and closing (flipping door), in addition to fixed facades and the possibility of manufacturing arches

- Places of use and installation: homes, buildings, residential towers, schools, hospitals, administrative and industrial buildings

Annual preventive measures to ensure the optimal functioning of windows and doors

Here are the simple annual maintenance tips that ensure Wintech upvc windows and doors work optimally :

The process of assembling the profiles by welding technique, as well as connecting the screws with strong metal (coated iron, thickness 1.25) ensures the stability of the meeting points and their non-dispersal with the progression of time and therefore the absence of the need for maintenance

Inspect the gaskets and replace the damaged ones

Clean the water outlet holes

Clean surfaces and sides, if necessary, with water and simple ordinary detergents only

As a result of the almost complete isolation of the place where windows and doors are installed, periodic ventilation is preferred to avoid high relative humidity that leads to the formation of fungi